The Role of Ergonomics in Control Room Design: Improving Comfort & Efficiency

Control rooms are the nerve centers of critical industries such as oil and gas, steel, power plants, aviation, cement, maritime, smart cities, and surveillance. Operators work long hours, managing high-stakes operations where accuracy is critical. A well-designed control room integrates workplace ergonomics to enhance both comfort design and efficiency, ensuring operators remain productive without compromising their health.

Importance of Ergonomics in Control Room Design

The science of creating a workplace that is in line with human capabilities is known as workplace ergonomics. This is translated into technology, equipment, and arrangement in control rooms that improve operators’ focus and responsiveness while lessening operator strain.

Key ergonomic aspects include:

- Adjustable features and lumbar support in ergonomic seating

- Footrests and Leg Rests to Avoid Fatigue During Extended Shifts

- Lighting and screen positioning to reduce eye strain

- Desk heights that can be adjusted for standing and sitting

- Appropriate workstation spacing to lessen distractions and stress

By focusing on these aspects, control rooms can maintain high performance while minimizing operator fatigue and long-term musculoskeletal issues.

Ergonomic Seating: Enhancing Operator Comfort

Ergonomic seating plays an important role in preventing back pain and improving posture. Control room chairs should have these features:

- Adjustable seat height and depth

- Proper lumbar support

- Armrests that align with the desk height

- Swivel and mobility feature to facilitate movement

A well-made chair helps users maintain proper posture, which eases back pain and improves concentration. Prolonged use of an inadequately built chair can lead to decreased productivity, poor blood circulation, and chronic pain. Operators can sustain optimal performance throughout their shifts by reducing these risks with the use of ergonomic seating.

Workplace Ergonomics and its Impact on Efficiency

A poorly designed workspace leads to discomfort, reducing an operator’s efficiency over time. Workplace Ergonomics improves productivity by:

- Minimizing physical strain, allowing operators to stay attentive for extended periods

- Reducing movement-related fatigue with strategically placed controls and displays

- Lowering the risk of workplace injuries, including repetitive strain injuries (RSI)

Ergonomic control rooms offer a smooth operational flow, lowering errors and speeding up reaction times. Adaptable workstations and sit-stand desks can further boost employee engagement and lower the risk of operator burnout.

Comfort Design: Addressing Operator Well-Being

Comfort design in control rooms goes beyond seating. It includes:

- Adjustable Workstations: Allowing operators to alternate between sitting and standing

- Ambient Lighting: Reducing glare and eye strain

- Noise Control: Acoustic solutions to minimize distractions

- Climate Control: Maintaining a temperature that supports productivity

A healthy workplace is ensured by a well-balanced space with enough ventilation and climate control to avoid discomfort. In order to avoid strain and overextension, comfort design also takes operator interaction into account by placing all control systems in convenient locations.

Leg Rest and Footrest: Essential for Operator Health

Operators often remain seated for long hours, leading to circulation issues and discomfort. A leg rest and footrest help in:

- Reducing lower back pressure

- Improving blood circulation

- Encouraging a natural sitting posture

Providing proper foot support prevents fatigue, ensuring that operators remain alert and responsive. Foot and leg rests alleviate stress on the legs, reducing swelling and discomfort, which is crucial for operators working in high-pressure environments.

Optimizing Control Room Layout for Maximum Efficiency

Beyond ergonomic seating and comfort design, control room layouts should ensure ease of movement and access. A well-planned layout:

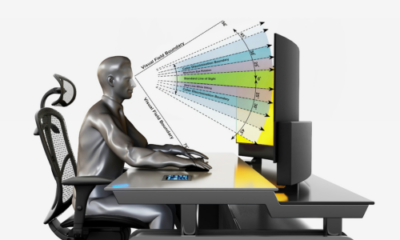

- Ensures screens and consoles are positioned at optimal viewing angles

- Minimizes unnecessary movement, allowing operators to concentrate

- Enhances workflow by keeping essential tools within reach

Businesses that depend on making decisions in real time include the oil and gas, aviation, and smart city surveillance sectors. Response time is decreased, and operational efficacy is increased in a control room that is well-organized.

Industry-Specific Ergonomic Solutions

Control rooms cater to industries where, making decisions in real-time is crucial. Oil and gas, power plants, smart cities, and monitoring centers demand workplaces that enable continuous monitoring and quick response. Ergonomic design enhances operators’ ability to manage multiple screens, alarms, and controls without unnecessary strain.

For industries such as marine and aviation, where operators need to handle high-pressure scenarios, ergonomic elements such as adjustable workspaces, proper lighting, and advanced seating solutions are crucial. These industries cannot afford lapses in decision-making due to discomfort or fatigue, making workplace ergonomics an operational necessity.

How Pyrotech Workspace Solutions Transforms Control Room Ergonomics

Established in 2006, Pyrotech Workspace Solutions has been at the forefront of designing and manufacturing world-class control room solutions. With a track record of delivering over 60,000+ Consoles & 450+ Control Rooms, expertise lies in creating highly functional workspaces tailored for critical industries. From Ergonomic Seating to customized workplace ergonomics, every detail is engineered to maximize operator comfort and efficiency.

Advanced comfort design is incorporated into control rooms created by Pyrotech Workspace Solutions, guaranteeing smooth operation and long-term health advantages for operators. Adjustable workstations, leg and footrest alternatives, and ideal screen placements that adhere to contemporary ergonomic principles are some solutions.

No Comments