Tata Steel Limited Kalinganagar

Location – Kalinganagar, Odisha

Year – 2024

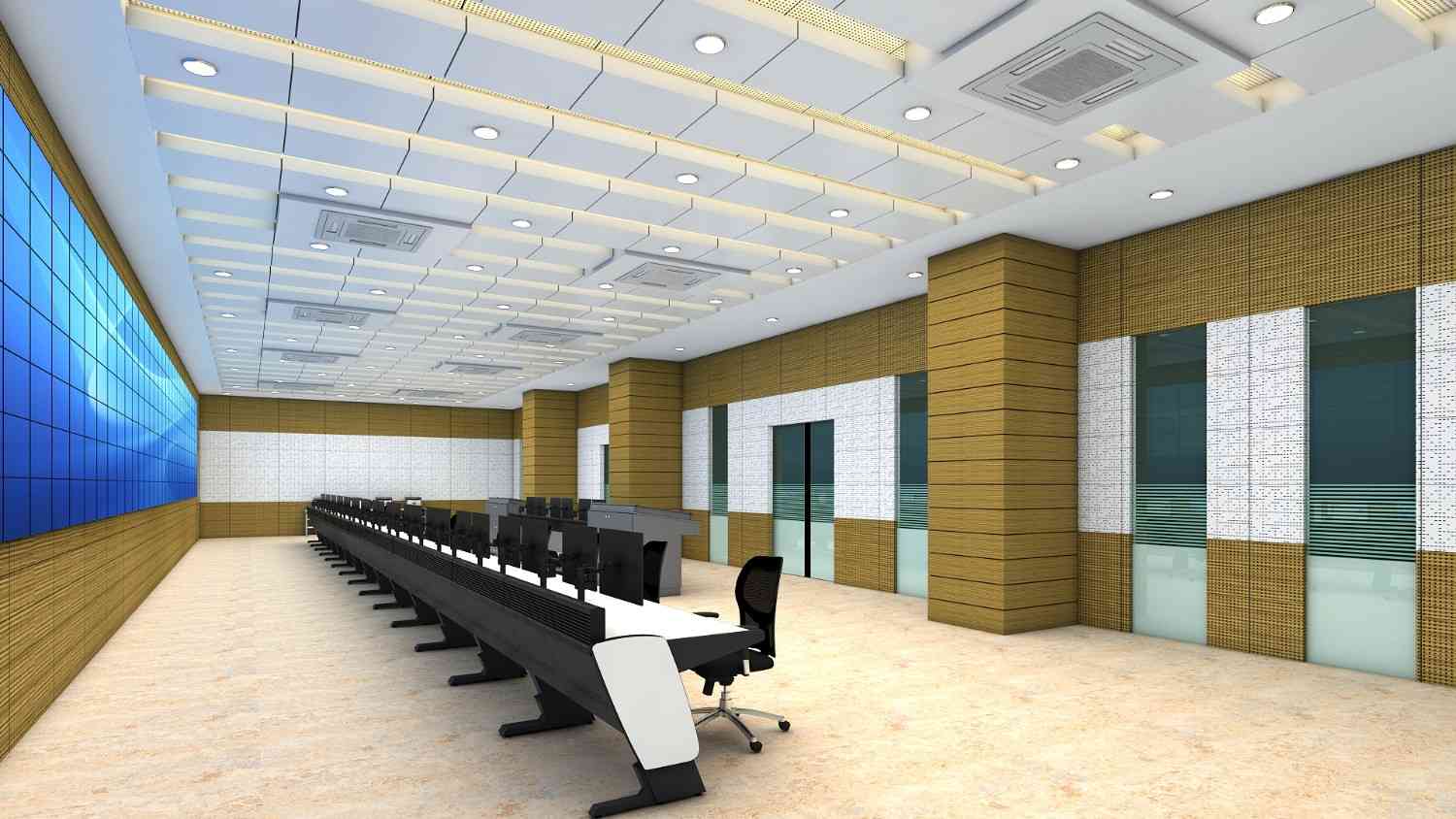

Project – Control Room Interior for Blast Furnace 2 ECR

Area – 3000 Sq. Ft.

The Tata Steel Kalinganagar project required the transformation of a 3000 sq. ft. space into a highly functional and visually appealing control room. Pyrotech Workspace took charge of designing, fabricating, and installing key interior elements that not only enhanced the workspace’s aesthetics but also optimized its functionality to support smooth operations.

By delivering an integrated solution for the control room, Pyrotech Workspace helped enhance the efficiency of Blast Furnace 2 operations. The careful selection of materials and design ensured that the control room facilitated a smooth flow of operations, while also providing a comfortable and organized environment for the workforce. Every element, from partitioning to the lighting, contributed to improving both workflow and visual appeal.

Project Scope

The scope of the project included the following key installations:

-

‣ Ceiling:

The ceiling was meticulously designed to create an inviting yet highly functional workspace. Using durable and aesthetically pleasing materials, not only enhances the visual appeal but also improves the acoustics of the control room. The installation was tailored to meet the room’s specific environmental conditions, ensuring long-term resilience and ease of maintenance.

-

‣ Paneling/Partition:

Custom paneling and partitions were installed to provide both structure and flexibility within the control room. These elements were carefully designed to maintain an open and collaborative environment while offering defined spaces for operational tasks. The paneling materials were chosen for their durability and their ability to blend seamlessly with the overall design theme.

-

‣ Flooring:

The flooring was selected for its high performance in heavy-use environments, ensuring durability while adding to the room’s modern aesthetic. The choice of material was made with the goal of minimizing wear and tear, while also contributing to the comfort and safety of the workforce. The installation process was precise, with an emphasis on ensuring a clean, polished finish that complements the room’s overall design.

-

‣ Doors and Glass:

High-quality doors and glass partitions were installed to foster visibility and communication between various sections of the control room. The glass was chosen for its clarity and strength, offering an unobstructed view while maintaining the room’s sleek appearance. The doors were designed to ensure easy access and contribute to the smooth operation of the room without compromising on design.

-

‣ LED Lights and Wiring:

Energy-efficient LED lights were strategically installed to provide optimal lighting for the control room, ensuring visibility without causing strain. The lighting system was integrated with the control room’s wiring infrastructure to offer a seamless, reliable power supply, contributing to a well-lit, productive environment. These lighting solutions also align with the room’s overall design, enhancing the visual quality of the workspace.

‣ Logo Installation

A prominent installation of the Tata Steel logo was included, serving as a visual representation of the company’s legacy and strength. Positioned strategically, the logo adds a corporate touch to the control room, reinforcing brand identity while contributing to the overall design theme. The installation was completed with attention to detail, ensuring it became a seamless part of the room’s visual narrative.

-

‣ Shoe Rack, Coat & Helmet Stand:

Practical storage solutions such as shoe racks, coat stands, and helmet holders were installed to ensure a clean and organized work environment. These installations were designed with functionality and space-saving in mind, providing easy access to essential items while maintaining the room’s professional appearance. Each unit was custom-made to match the room’s interior theme, blending functionality with aesthetic appeal.

Implementation and Execution

During the implementation phase, Pyrotech Workspace paid meticulous attention to every detail, ensuring that each element of the control room was perfectly integrated. From the precision of partition placement to the optimal positioning of lighting and wiring, every aspect was executed with excellence in mind. The installation process was aligned with the project’s operational goals, ensuring minimal disruption to the ongoing operations of the Blast Furnace 2.

Project Gallery